A Comprehensive Guide to Boosting Industrial Automation Efficiency in the fast-paced world of industrial automation, staying ahead of the competition requires harnessing the full potential of cutting-edge technology. And when it comes to performance and reliability, the Allen Bradley PLC stands out as a game-changer. Whether you're an engineer, a plant manager, or an automation enthusiast, this comprehensive guide is your go-to resource for unlocking the untapped efficiency of Allen Bradley PLC.

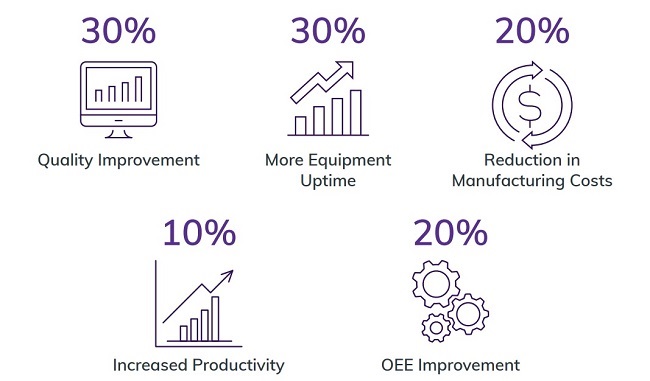

With its robust features and advanced capabilities, the Allen Bradley PLC empowers businesses to streamline their operations, minimize downtime, and enhance productivity. This guide takes a deep dive into the intricacies of Allen Bradley PLC, offering practical tips, real-world examples, and step-by-step instructions to optimize your industrial automation systems.

From programming fundamentals to troubleshooting techniques, we've got you covered. Discover how to leverage Allen Bradley PLC's unrivalled engineering tools, integrate it seamlessly with other automation components, and maximize its potential in various industries. Let this comprehensive guide be your roadmap to unlocking the full potential of Allen Bradley PLC and driving your automation efficiencies to new heights.

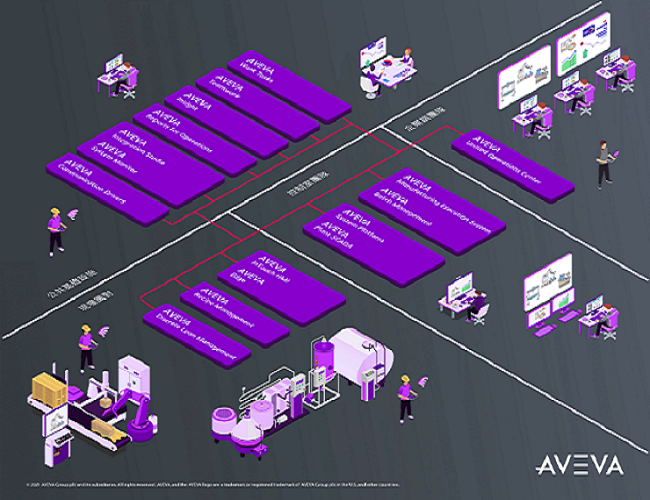

Understanding Rockwell software

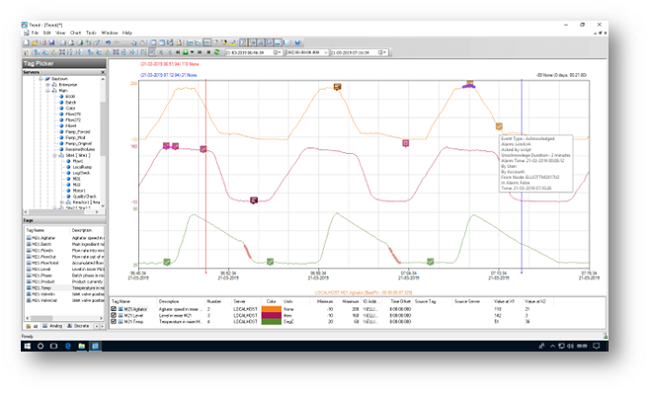

The suite consists of several software programs, each designed to address a different facet of the automation process. At the heart of Rockwell platform is RSLogix 5000, which stands as a robust and adaptable PLC programming platform.

The user-friendly and intuitive interface offered by RSLogix 5000 enables control and automation experts to efficiently develop logic for Allen-Bradley PLCs.

The power of studio 5000

Studio 5000’s Integrated Motion on EtherNet/IP capability elevates industrial automation to new heights by enabling engineers to handle motion control directly from the PLC.

This means motions tasks such as coordinated motion, camming, and gearing can be seamlessly integrated with the logic program, reducing the need for separate motion controllers and simplifying the control architecture.

A more robust and dependable system can be created by engineers who can effectively monitor and track changes to the control system, making sure that any upgrades or alterations are recorded and preserved.

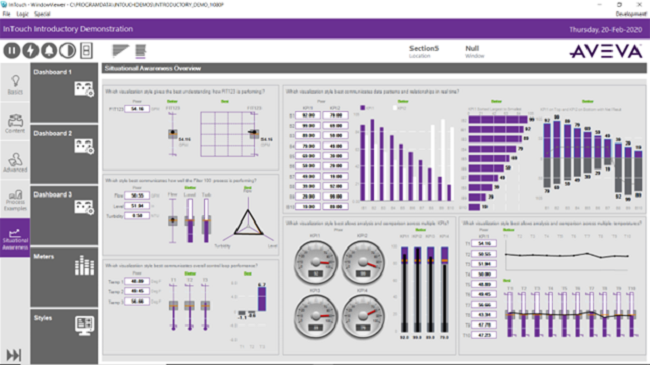

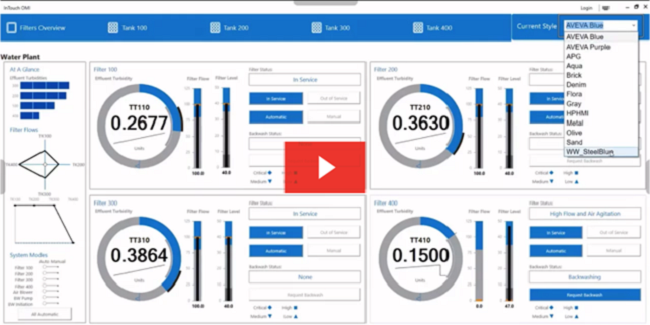

The HMI design environment allows for the creation of intuitive dashboards, trends, and alarm displays, fostering efficient process monitoring and decision-making.

Unleashing the potential of FactoryTalk view

FactoryTalk View, a key component of Rockwell Software, is a powerful Human-Machine Interface (HMI) software that bridges the gap between human operators and industrial processes.

As a control and automation engineer, understanding FactoryTalk View is essential for designing visually appealing and user-friendly interfaces that enhance operator efficiency and plant productivity.

FactoryTalk View offers a versatile design environment with a wide range of graphical elements, animation options, and data display capabilities.

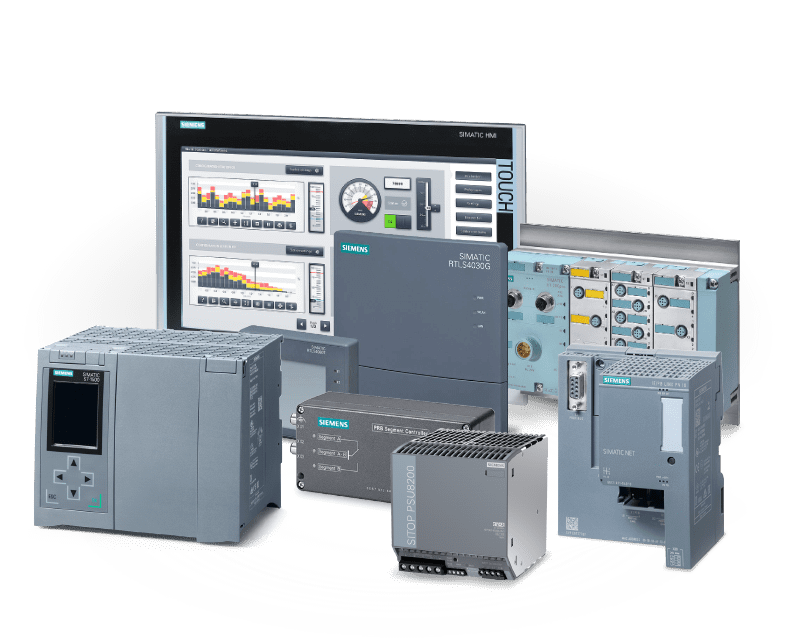

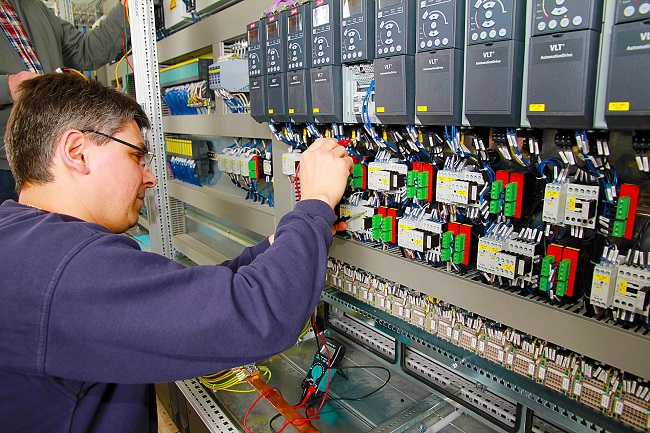

Introduction to Allen-Bradley PLC hardware

As a control and automation engineer, the choice of hardware plays a vital role in the success of any automation project.

The Rockwell Automation brand Allen-Bradley PLC Hardware is well known for its scalability, dependability, and wide range of applications.

This comprehensive range of controllers caters to diverse industries and applications, providing engineers with the flexibility needed to address a wide array of automation challenges.

The Allen-Bradley PLC family includes ControlLogix, CompactLogix, MicroLogix, and PLC-5 series.

ControlLogix PLCs

ControlLogix PLCs, part of the Logix family, exemplify the pinnacle of Allen Bradley’s hardware offerings.

These high-performance controllers have a lot of I/O points and a lot of memory; they are made for demanding and sophisticated automation systems.

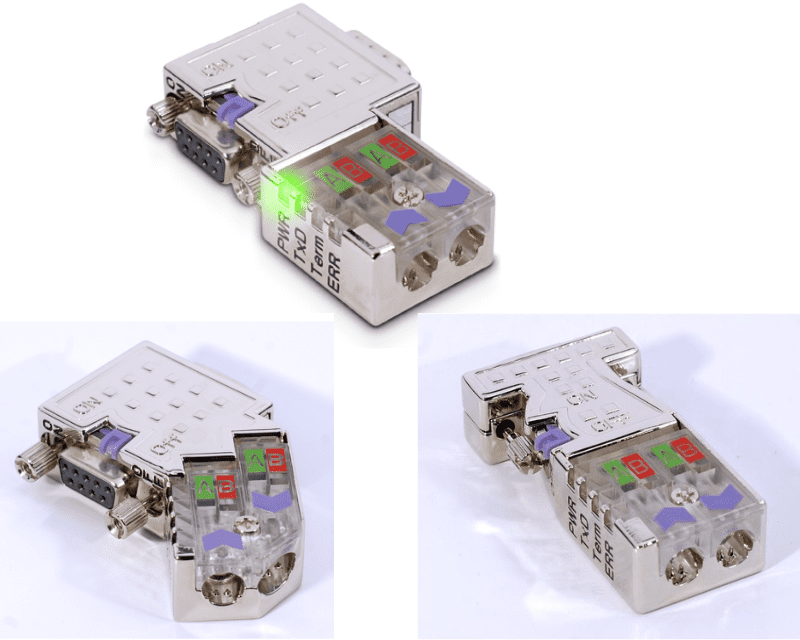

ControlLogix PLCs support various communication protocols, such as EtherNet/IP, ControlNet, and DeviceNet, ensuring seamless integration with other industrial devices.

Engineers can leverage the flexibility of ControlLogix PLCs by mixing and matching different I/O modules to accommodate a wide range of sensors and actuators.

CompactLogix PLCs

Allen Bradley CompactLogix PLCs offer the same reliability and performance as ControlLogix but in a more compact form factor.

These controllers are perfect for machine control and smaller automation projects since they are made for applications where space is at a premium.

CompactLogix PLCs can nevertheless manage a sizable number of I/O points and support a variety of communication protocols in spite of their reduced size.

Engineers can use CompactLogix PLCs in a variety of applications, from distributed control systems to standalone devices, thanks to their scalability.

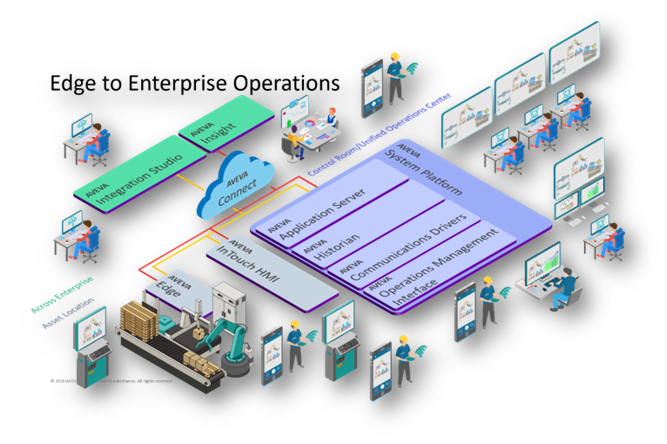

RSLogix 5000, Studio 5000, and FactoryTalk View from Rockwell Software offer an easy-to-use, integrated environment for creating, coding, and visualizing automation systems.

Because of its adaptability, Allen-Bradley PLC Hardware including the ControlLogix and CompactLogix series can be used for a wide range of applications and projects, regardless of size or complexity.

The combination of Allen-Bradley PLC Hardware and Rockwell Software optimizes development, increases output, and promotes effective communication across automation specialties.

If you are looking for any Industrial Automation solutions reach us at contact@asteamtechno.com for

Support | Solution | Inquiry | Upgradation | Modification