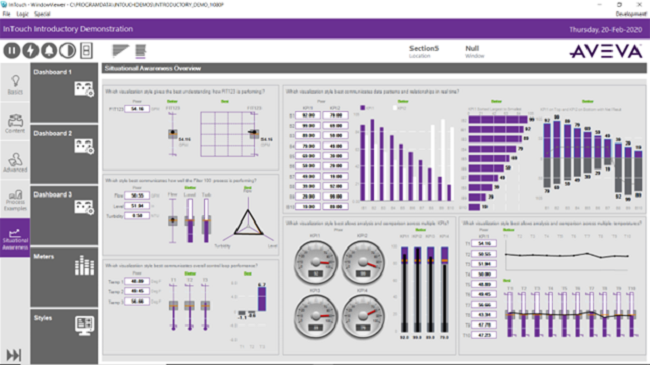

Human-Machine Interface (HMI) is critical in enabling effective control and monitoring of complex systems in the realm of industrial automation.

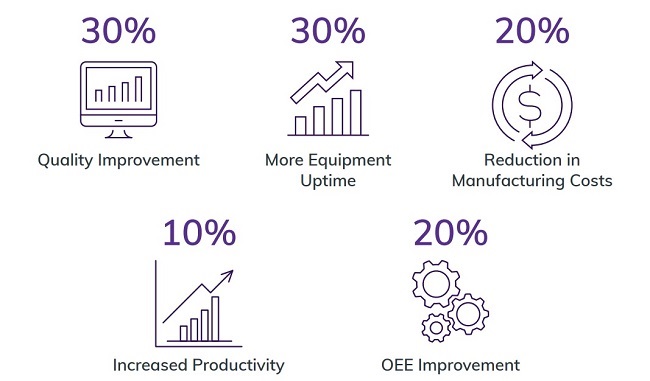

Industrial process productivity, safety, and overall performance can all be greatly improved with a well-designed HMI. I have direct experience with the effects of high-performance HMI design as a Control and Automation Engineer.

1. User-Centric Approach

It is critical to prioritize the user while designing a high-performance HMI.

Participate in group discussions and user workshops to gain an understanding of operators' requirements and expectations.

You will be able to learn a great deal about their preferences, workflow, and pain issues through this procedure.

A user-centric design process can help you produce an HMI that is more intuitive and user-friendly by matching it with operators' mental models.

Test the usability of the design with end users to see how well it works, and get their input so you can keep improving the interface over time.

Refrain from providing the operators with an excessive amount of information and details.

Concentrate on the essential data required for making decisions and expedite the presentation of less important material by using layers or context-based information.

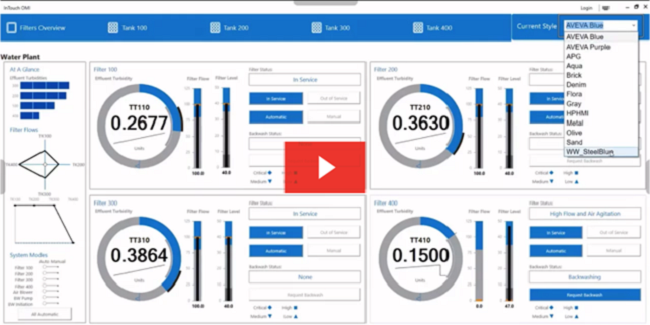

Visual recognition can be improved by using meaningful icons and symbols, and different states or statuses can be successfully communicated by colour coding.

But be careful—using too many colours can distort the image and make it harder to read.

Aim for a minimally cognitively taxing interface that is aesthetically pleasing and well-organized.

2. Consistency in Layout and Navigation

Consistency fosters familiarity and efficiency in operating the HMI. Maintain uniformity in the placement of controls and indicators, ensuring that operators can easily find the functionalities they require, regardless of their location on the HMI.

A consistent layout also reduces the need for excessive retraining when operators switch between different parts of the system.

Establish a logical and transparent hierarchy for navigation so that users may access various displays and capabilities.

Utilize menu structures or tabs that group related functions together, allowing operators to navigate effortlessly through the system.

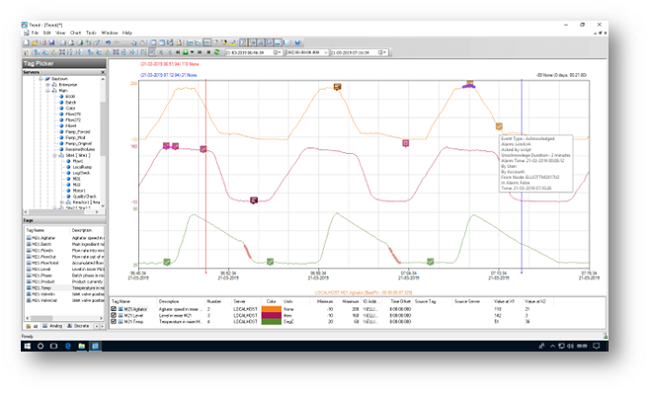

3. Alarm Management and Prioritization

An intelligent alarm management system is crucial for maintaining the safety and stability of industrial processes.

Categorize alarms based on their severity and urgency, and prioritize them accordingly.

High-priority alarms should be displayed more prominently and accompanied by audible alerts to ensure immediate attention.

Include clear and concise alarm messages that offer operators sufficient information to identify the issue and make appropriate decisions.

Consider providing contextual information alongside alarms to help operators troubleshoot and resolve the root cause effectively.

4.Context-Sensitive Help and Documentation

Include context-sensitive support in the HMI so that operators may get help right away when they need it or run into unexpected scenarios.

One way to improve operator autonomy and lessen reliance on outside assistance is to link certain screens or alarms to pertinent paperwork, troubleshooting manuals, or standard operating procedures.

Provide easily available tutorials and documents that cover popular tasks and procedures as well.

These tools support operator training and serve as helpful resources for seasoned staff in rare situations.

5. Feedback and Confirmation Mechanisms

When operators interact with controls or make selections, the interface should visually respond with changes, such as button presses, colour changes, or animation.

For critical operations, incorporate confirmation mechanisms to avoid unintended actions.

Operators should receive clear prompts or verification dialogs when initiating significant commands, ensuring they have the opportunity to confirm their intentions before executing potentially irreversible actions.

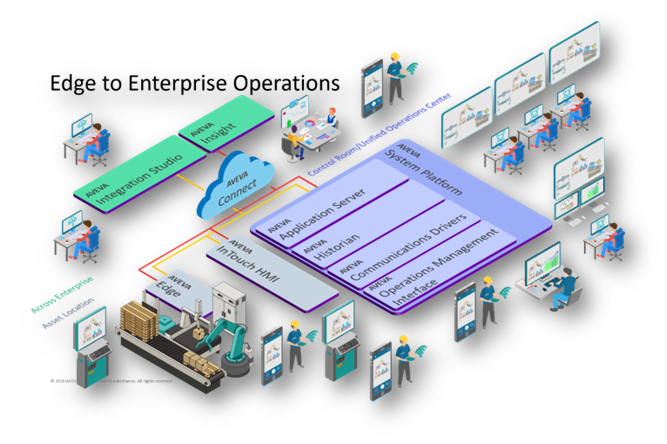

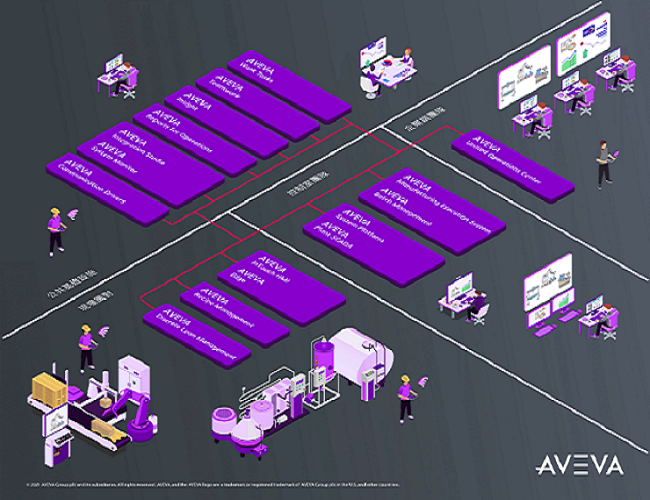

6. Scalability and Flexibility

Design the HMI with scalability and flexibility in mind to accommodate future expansions and changes in the industrial process.

Consider potential system upgrades, new functionalities, or the integration of additional equipment.

Make sure that as the system expands, the HMI's design and navigation stay logical and simple to use.

Flexible data display techniques and adaptive screen layouts will enable the HMI to accommodate changing needs without compromising usability.

Achieve a high-performance HMI by making it as quick and responsive as possible.

This involves considering the capabilities of the underlying hardware, software, and network infrastructure.

Minimize data update delays to provide real-time information to operators.

Invest in advanced hardware and software technologies, such as high-speed processors and optimized graphics libraries, to ensure smooth and seamless interaction.

Test the HMI's functionality under various loads and circumstances to find bottlenecks early on and fix them.

As a Control and Automation Engineer, adopting the concepts of high-performance HMI design is a path of ongoing development.

You can design HMIs that greatly improve operator efficiency, safety, and decision-making skills by taking a user-centric approach, keeping things simple, making sure everything is consistent, handling alarms well, offering context-sensitive assistance, adding feedback mechanisms, and building for scalability and responsiveness.

In the dynamic realm of industrial automation, human-machine interfaces (HMIs) continue to play a crucial role in enabling smooth human-machine communication.